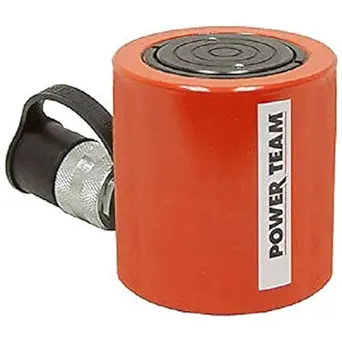

Built for power and precision, the Power Team R1506D delivers a massive 150-ton capacity with a 6-inch stroke for demanding lifting, pressing, and pushing jobs. Its double-acting design provides powered extension and retraction for smooth, controlled movement in any position.

Operating at 10,000 psi, this cylinder combines high output force with a precision-machined alloy steel body for unbeatable strength and durability. Wear-resistant seals and Power-Tech surface treatment ensure long life, even in the toughest environments.

Perfect for heavy equipment maintenance, bridge work, fabrication, and press systems, the R1506D’s dual ports deliver faster return speeds and superior control over single-acting models.

When your operation demands raw power, precise control, and proven reliability, the R1506D is built to perform—cycle after cycle.